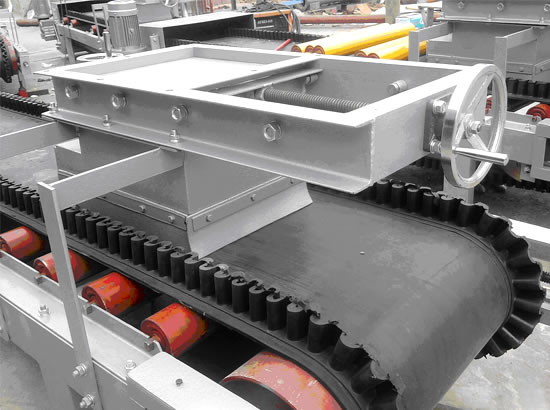

JGC-40 Type Weighing Feeder/Coal Feeder

Scope of Application

The JGC-40 type weighing feeder is a feeding and metering equipment that integrates a belt feeder, an electronic belt scale, and a frequency conversion electric control system. It is widely used in industries such as metallurgy, electric power, coking, chemical engineering, building materials, and docks.

Working Principle

When materials pass through, they act on the weighing sensor through the force transmission mechanism, generating a voltage signal proportional to the belt load and sending it to the integrator. Meanwhile, the integrator receives the pulse signal proportional to the belt speed generated by the speed sensor. Through the integral operation of the weight signal and the speed signal, the instantaneous flow rate and the cumulative flow rate of the materials are obtained.

System Characteristics

The weighing sensor adopts double-layer sealing, featuring a long service life and good stability.

The speed signal adopts a photoelectric encoder, which is accurate, reliable, and has strong anti-interference ability.

With a unique anti-deviation technology, it ensures the normal operation of the belt.

It has functions of automatic zero adjustment, automatic interval adjustment, and automatic fault diagnosis.

Optional open-loop or closed-loop control can realize single-loop intelligent control of the system.

Optional various alarm devices, such as for material blockage, material breakage, and belt deviation, enabling timely understanding of the on-site situation in the control room.

Optional instrument interfaces: RS232 or RS485 interfaces and printer interfaces.

This equipment can serve as the basic unit of the ZNPL-3000 type batching system.

Main Technical Parameters

Metering accuracy: ±0.5% (±0.25% optional)

Belt width: 500 ~ 1400 mm (specially designed for non-standard requirements)

Conveying capacity: 0.5 ~ 1000 t/h

Center distance between the inlet and outlet: >1200 mm

Speed regulation method: frequency conversion regulation

Current output: 0 ~ 20 mA or 4 ~ 20 mA

Material particle size: ≤100 mm

Communication interface: RS232 or RS485

Working Conditions and Installation Conditions

Environmental Temperature:

Instrument: -10°C ~ 50°C

Mechanical: -20°C ~ 60°C

Power Supply Voltage:

220/380 VAC (+10%, -15%), 50 HZ (±2%)