Full-suspended single-idler structure, with a dynamic cumulative error of less than ±1%. It is applicable to occasions where the accuracy requirement is not high and the installation requirement is simple. It can provide instantaneous flow rate and cumulative amount for the process control and production monitoring in product manufacturing.

Product Features:

Full-suspended single-idler structure;

Equipped with 2 high-precision tension-type weighing sensors;

Stronger adaptability, simple structure, and quick installation.

The ICS-30 electronic belt scale has a dynamic cumulative error of less than ±1%. It is applicable to occasions where the accuracy requirement is not high and the installation requirement is simple. It can provide instantaneous flow rate and cumulative amount for the process control and production monitoring in product manufacturing.

The YK-ICS-30B electronic belt scale has the same structure as the YKJ-ICS-30A type, except that it has only 1 weighing sensor, one less than the YK-ICS-30A type. With only one weighing sensor, if it is damaged, the metering cannot continue. Therefore, this type of belt scale is only applicable to occasions where the budget is low, the accuracy requirement is not high, the installation is convenient, the installation space is small, and the value of the conveyed materials is low.

Working Principle

The weighing bridge is installed on the conveyor frame. When materials pass by, the weighing idlers detect the weight of the materials on the belt conveyor. Through the lever action, a voltage signal proportional to the belt load is generated on the weighing sensor. The speed sensor is directly connected to the large-diameter speed measuring roller, providing a series of pulses. Each pulse represents a belt movement unit, and the pulse frequency is proportional to the belt speed. The weighing instrument receives signals from the weighing sensor and the speed sensor, and through integral operation, obtains an instantaneous flow value and a cumulative weight value, which are then displayed respectively.

Four Major Structural Components

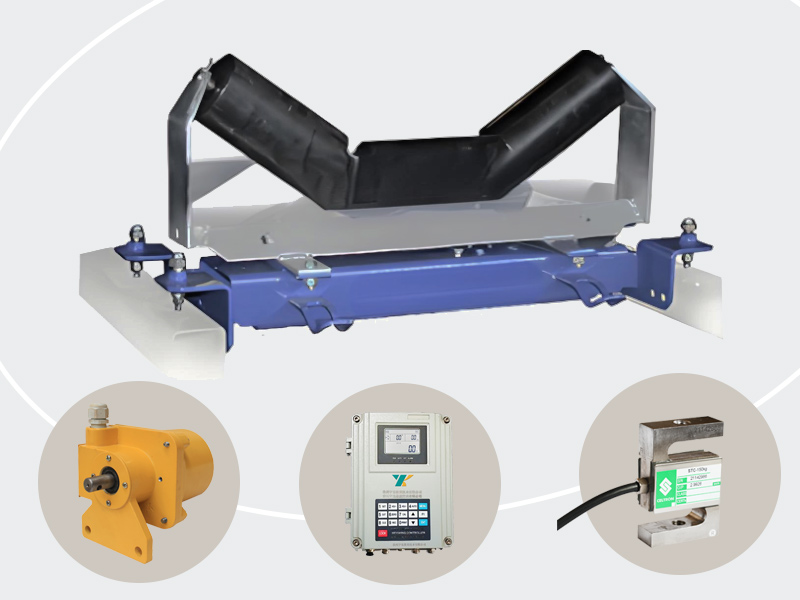

The ICS-30 type electronic belt scale consists of four parts: ICS-30 type suspended weighing bridge, weighing sensor, YK-12 type speed sensor, and YK2015 weighing controller.

Weighing Bridge

The single-idler ICS-30 type weighing bridge adopts a non-lever, full-suspended structural design, which is stable and reliable. The calibration with chain code of this structural design is basically close to the actual object calibration value. It is fully enclosed, moisture-proof, dust-proof, corrosion-proof and can reduce material accumulation. It will not have the problem of unstable zero point caused by the use of knife-edge devices and bearing devices. It has a one-piece structure with no moving parts, so it is easy to install and requires no maintenance.

Structural Characteristics

Simple structure with few force transmission links, and convenient and straightforward installation;

Adopting a non-lever, full-suspended structure with a single idler and a small weighing area;

Equipped with two weighing sensors, which are less affected by eccentric loading;

Mainly used on belt conveyors with a short distance between the inlet and outlet centers.

Main Technical Parameters:

System accuracy: ±1%

Weighing range: 1~4000 t/h

Belt width: 300~1400 mm

Belt speed: 0.1~4 m/s

Inclination angle of belt conveyor: < 10°