The dynamic cumulative error is less than ±0.5%. It can accurately conduct continuous measurement on bulk materials and provide reliable data support for enterprises' production management, cost accounting, product quality control and so on. It is applicable to multiple industries and scenarios. For example, it can be well applied to the measurement of various bulk materials in the belt conveyor systems of industries such as electric power, metallurgy, chemical engineering, building materials and ports. Whether it is blocky materials or powdery materials, and regardless of whether it is the transportation with large or small flow rates, the ICS-20B can perform measurement stably and accurately.

Working Principle

The weighing bridge is installed on the conveyor frame. When materials pass by, the metering idler detects the weight of the materials on the belt conveyor and applies a force to the weighing sensor through the lever, generating a voltage signal that is proportional to the belt load. The speed sensor is directly connected to the large-diameter speed measuring drum and provides a series of pulses. Each pulse represents a belt movement unit, and the frequency of the pulses is proportional to the belt speed. The weighing instrument receives signals from the weighing sensor and the speed sensor, and obtains an instantaneous flow value and a cumulative weight value through integral operation, and displays them respectively.

System Composition

The ICS-20B electronic belt scale consists of four parts: the ICS-20B lever-type weighing bridge, the weighing sensor, the YK-12 speed sensor and the YK2015 weighing controller.

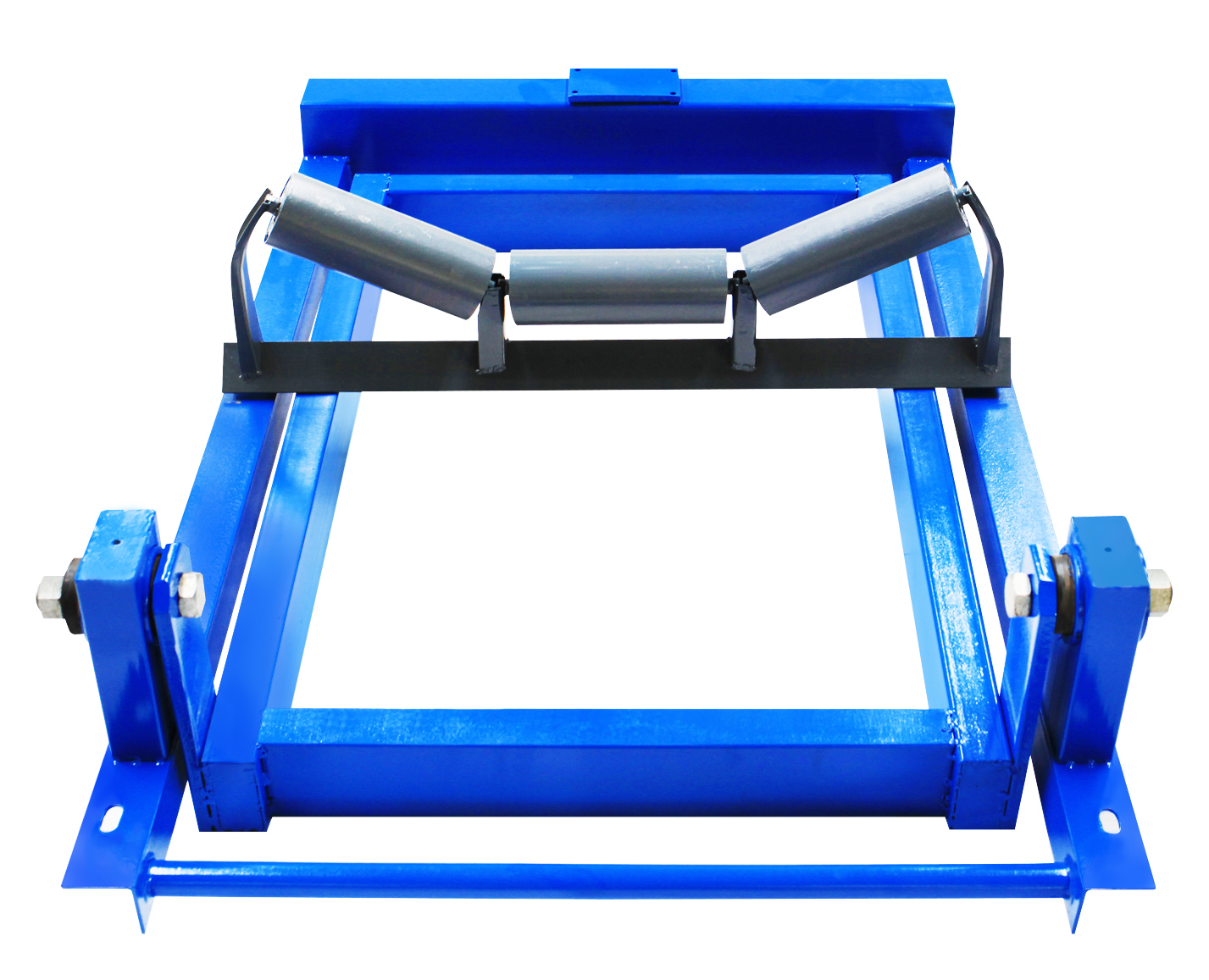

Weighing Bridge

The ICS-20B weighing bridge is equipped with a set of rollers on a single lever. It adopts a pull-type sensor. The intermediate support and the outer support use frictionless trunnion pivots. The main beam of the weighing bridge adopts a rectangular steel pipe, which has sufficient rigidity, a relatively small self-weight and the minimum surface area for dust accumulation. To ensure the stability of the whole system, the high-precision resistance strain gauge sensor is installed at the tensioned part, which is resistant to lateral forces and can reduce non-linear errors. For the measurement of materials with relatively low specific gravity, a counterweight scale frame can be adopted.

Structural Characteristics

It has a simple structure with few force transmission links and is easy and convenient to install.

It has a unique rectangular lever with good rigidity and no deformation. It uses frictionless rubber trunnion supports, which are corrosion-resistant, moisture-proof and anti-vibration.

It is resistant to lateral forces and horizontal component forces, effectively reducing the impact of belt deviation and material falling deviation on the system accuracy.

The weighing sensor is of the pull type, which is flexible in adjustment and convenient in installation.