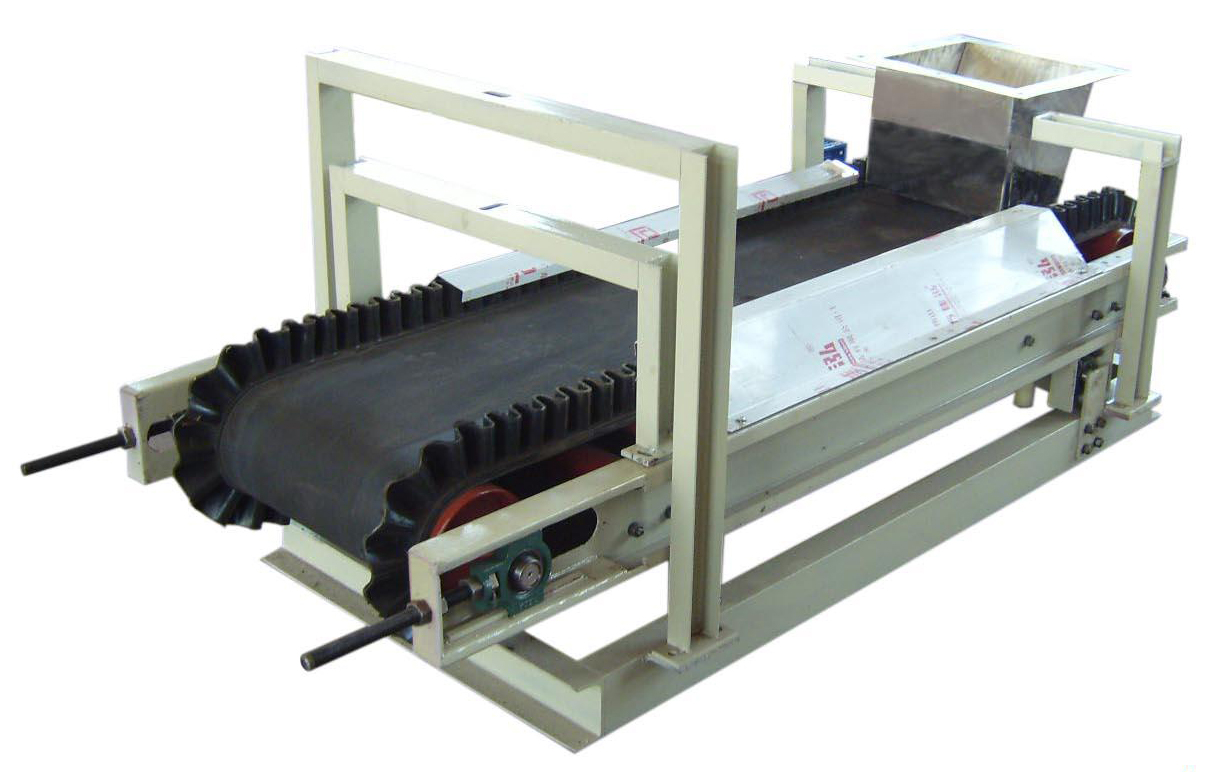

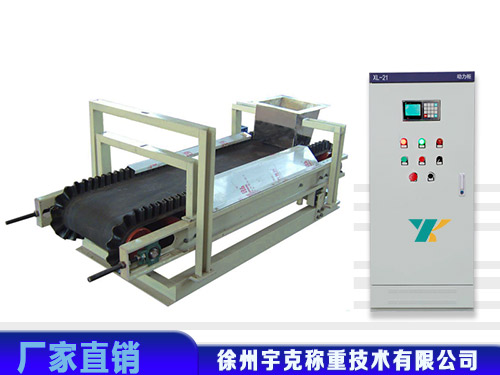

The YKL-50 Type Quantitative Feeder is a new-generation product of our company. It features high measurement and control accuracy as well as stable performance. Its unique and optimized design enables it to be used under harsh working conditions. By adopting corresponding structural characteristics and hopper forms according to specific situations, it economically solves many problems in the feeding process. It is widely used for the quantitative conveying of granular materials in industries such as building materials, metallurgy, iron and steel, chemical engineering, coal, and ceramics.

Working Principle

The load and speed signals of the conveyor belt are sent to the measurement, control, and adjustment system controlled by the microprocessor for processing. The actual feeding rate is continuously compared with the set feeding rate, thereby controlling the speed of the conveyor belt to keep the feeding rate at a constant level.

System Characteristics

The driving and driven rollers use self-aligning bearings, making the installation and adjustment extremely convenient.

The reducer in the driving mechanism is directly sleeved on the shaft of the driving roller through a hollow shaft. It has good sealing performance, sensitive speed adjustment, a compact structure, convenient installation, and reliable use.

The conveyor belt can be removed for replacement simply by loosening it and moving one side of the bracket.

The weighing frame is connected to the scale body frame through stainless steel cross reed springs, which not only serve as fulcrum but also as limiters.

The automatic tensioning device ensures the constant tension of the belt, thus guaranteeing the measurement accuracy.

The automatic deviation-correcting device prevents the belt from deviating within a certain range. When it exceeds the range, there is a deviation limit switch.

The internal and external cleaning devices for the belt not only protect the belt but also ensure the stability of the zero point.

It is equipped with a calibration weight bracket and special calibration weights, allowing the measurement accuracy to be verified at any time.

The instrument has an alarm function, and the alarm mode can be set according to actual needs.

With its unique design and complete protection functions, fully automatic unmanned operation can be achieved, which not only ensures the product quality but also improves the production efficiency of the production line.

Main Technical Parameters

System error: ≤ ±0.5%

Feeding capacity: 0.5 ~ 800 t/h

Operating environment:

Instrument: -30 ~ +45°C; Scale body: -30 ~ +50°C; Relative humidity: ≤ 90%

Power supply:

Instrument part: 220 VAC + 10%, 50 HZ; Driving part: 380 VAC ± 10%, 50 HZ

Working Conditions and Installation Conditions

Environmental temperature:

Instrument: -10°C ~ 50°C; Mechanical: -20°C ~ 60°C

Power supply voltage:

220/380 VAC (+10%, -15%), 50 HZ (±2%)