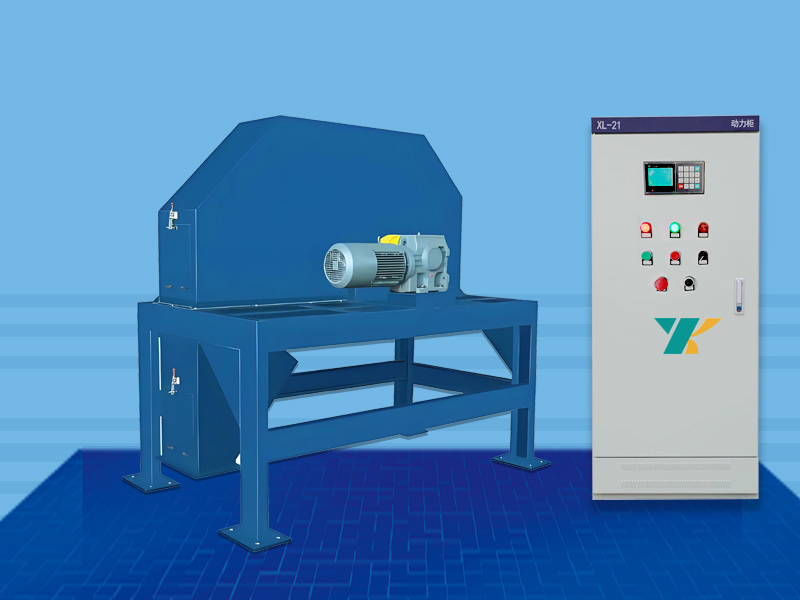

YKTC - D Type Belt Middle Sampling Machine

Belt Middle Sampling and Sample Preparation System

The middle sampling and sample preparation refer to the method that the primary sampling and sample preparation machine is installed in the middle position of the belt conveyor to directly collect subsamples from the horizontally or inclined running conveyor belt.

System Composition

A typical middle sampling and sample preparation system consists of two-stage sampling and sample preparation equipment. This system is composed of a rotary bucket type middle sampling machine, a primary sample feeder, a hammer crusher, a secondary sample feeder, a secondary sampling machine, and residue treatment equipment, etc.

System Working Process

The working process of this system is as follows: According to the programmed settings, the primary sampling machine rotates the sampling head once every certain time interval to collect a subsample. The subsample enters the sample feeder through the chute. The feeder continuously and evenly sends the sample into the crusher. The crusher crushes the subsample according to the specified particle size requirements. The crushed subsample enters the secondary feeder and undergoes secondary sampling and reduction by the secondary sampling machine. Finally, the final sample enters the sample collection tank, and the residue is input into equipment such as a bucket elevator or a screw conveyor to be returned to the main material flow.

Characteristics and Advantages of the Equipment

Adopting PLC technology, with a high degree of automation and reliable operation.

The system is compactly designed, saving space and suitable for low-altitude installation.

The unitized structure is convenient for on-site combined installation.

The careful design and material selection effectively prevent material blockage and spillage.