ICS-17B is in the form of a single lever and dual idlers. The length of its scale frame is half that of ICS-17A, and its metering accuracy is slightly lower. It is applicable to occasions where the accuracy requirement is relatively low. In some small processing and manufacturing factories, such as small food processing plants and small building materials factories, the production process is relatively simple and the material conveying volume is not large. ICS-17B can meet the accurate metering requirements for materials. For example, in a small food processing plant, it is used to meter the conveying volume of raw materials such as flour and sugar to ensure the accurate input of raw materials during the production process, thus guaranteeing the stability of product quality. For small building materials factories, such as those producing small prefabricated components, ICS-17B can meter the conveying of materials such as cement and sand and gravel to help enterprises control production costs and improve production efficiency.

Working Principle

The weighing bridge is installed on the conveyor frame. When materials pass by, the weighing idlers detect the weight of the materials on the belt conveyor. Through the lever action, a voltage signal proportional to the belt load is generated on the weighing sensor. The speed sensor is directly connected to the large-diameter speed measuring roller, providing a series of pulses. Each pulse represents a belt movement unit, and the pulse frequency is proportional to the belt speed. The weighing instrument receives signals from the weighing sensor and the speed sensor, and through integral operation, obtains an instantaneous flow value and a cumulative weight value, which are then displayed respectively.

System Composition

The ICS-17 type electronic belt scale consists of four parts:

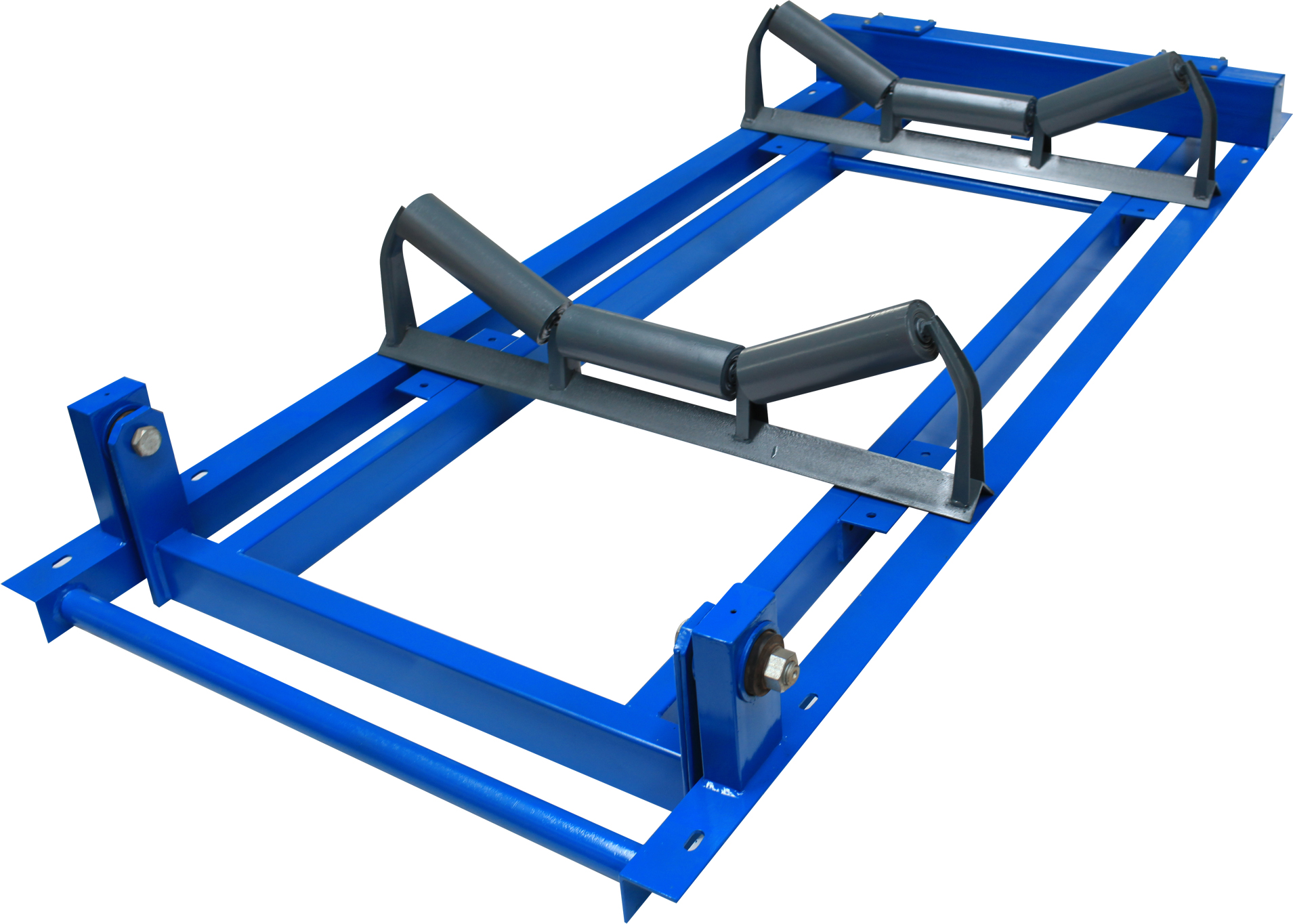

ICS-17 type weighing bridge: The ICS-17 type weighing bridge is equipped with two sets of idlers on the single lever. It is supported by two tension-type sensors in the middle, and the outer support adopts a frictionless trunnion pivot. This effectively overcomes the impact of eccentric loading on accuracy. This enclosed device can prevent vibration, moisture, corrosion and material accumulation, thus avoiding the problems caused by the use of knife-edge devices and bearing devices in harsh environments. The main beam of the weighing bridge adopts a rectangular steel pipe, which endows the entire weighing bridge with sufficient rigidity, a relatively small self-weight, and minimizes the surface dust accumulation area. To ensure the stability of the entire system, high-precision strain gauge sensors are installed in the tensioned parts to reduce non-linear errors.

Structural Characteristics

Simple structure, convenient and straightforward installation, with few force transmission links.

Unique rectangular levers with good rigidity and no deformation.

Frictionless rubber trunnion supports, which are corrosion-resistant, moisture-proof and vibration-resistant.

Resistant to lateral forces and horizontal component forces, effectively reducing the impact of belt deviation and material falling deviation on the system accuracy.

Simple structure, convenient and straightforward installation, with few force transmission links.